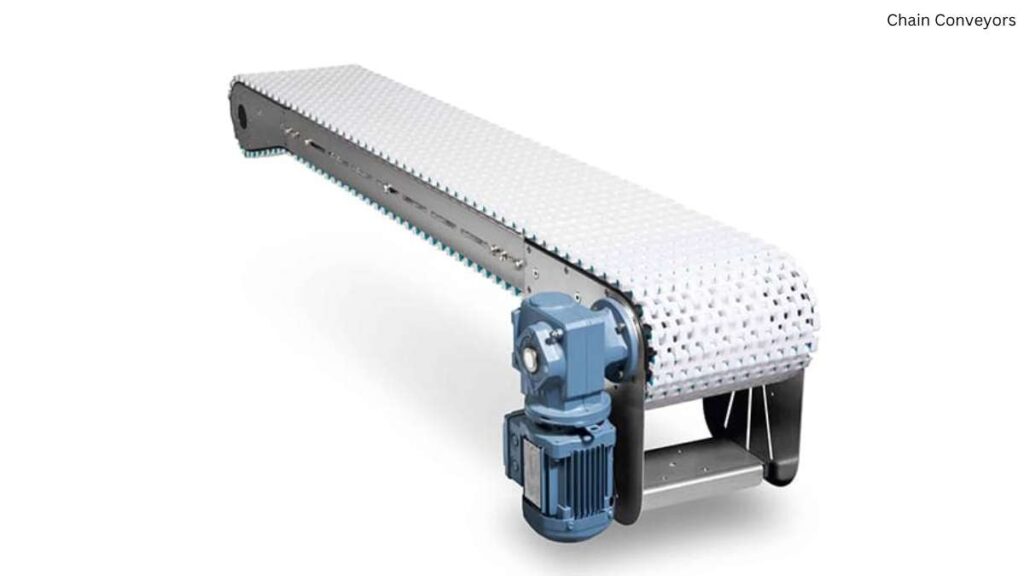

Chain Conveyors

Chain conveyors are a type of conveyor system commonly used in industries to move materials through production lines or processes. They are robust and versatile, making them suitable for transporting heavy, bulky, or irregularly shaped items over relatively short distances. Here’s an overview of chain conveyors:

Components:

- Chains: The main feature; chains are usually made of metal or strong materials to withstand wear and tear.

- Drive System: Powers the chain and ensures smooth motion.

- Conveyor Bed: Supports the chain and the load being transported.

- Attachments: Customizable fittings on the chains to hold or guide specific materials.

Types of Chain Conveyors:

- Drag Chain Conveyors: Move bulk materials in enclosed troughs using chains with paddles.

- Slat Chain Conveyors: Use slats (plates) attached to the chain to transport goods, often in packaging or assembly lines.

- Overhead Chain Conveyors: Suspended from above, used for moving materials in automotive or painting processes.

- Roller Chain Conveyors: Utilize rollers attached to the chain for smoother transport, often in heavy industries.

Applications:

Manufacturing: Transporting parts and assemblies.

Agriculture: Moving grain, seeds, or fertilizers.

Mining: Handling ore, coal, or other mined materials.

Warehousing: Moving pallets or heavy items.

Food and Beverage: Conveying packaged goods or crates.

Advantages:

Durable and capable of handling heavy loads.

Flexible designs to fit specific industrial needs.

Suitable for harsh environments, including extreme temperatures and abrasive materials.

Can operate horizontally, vertically, or at an incline.

Limitations:

Noise levels can be high, depending on the design and material.

Higher initial cost compared to some conveyor systems.

Requires regular maintenance to prevent chain wear or breakage.